Inspection Services

Brochure

Download our document to see specific data of the service and how we work.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

Our Services

How can we help?

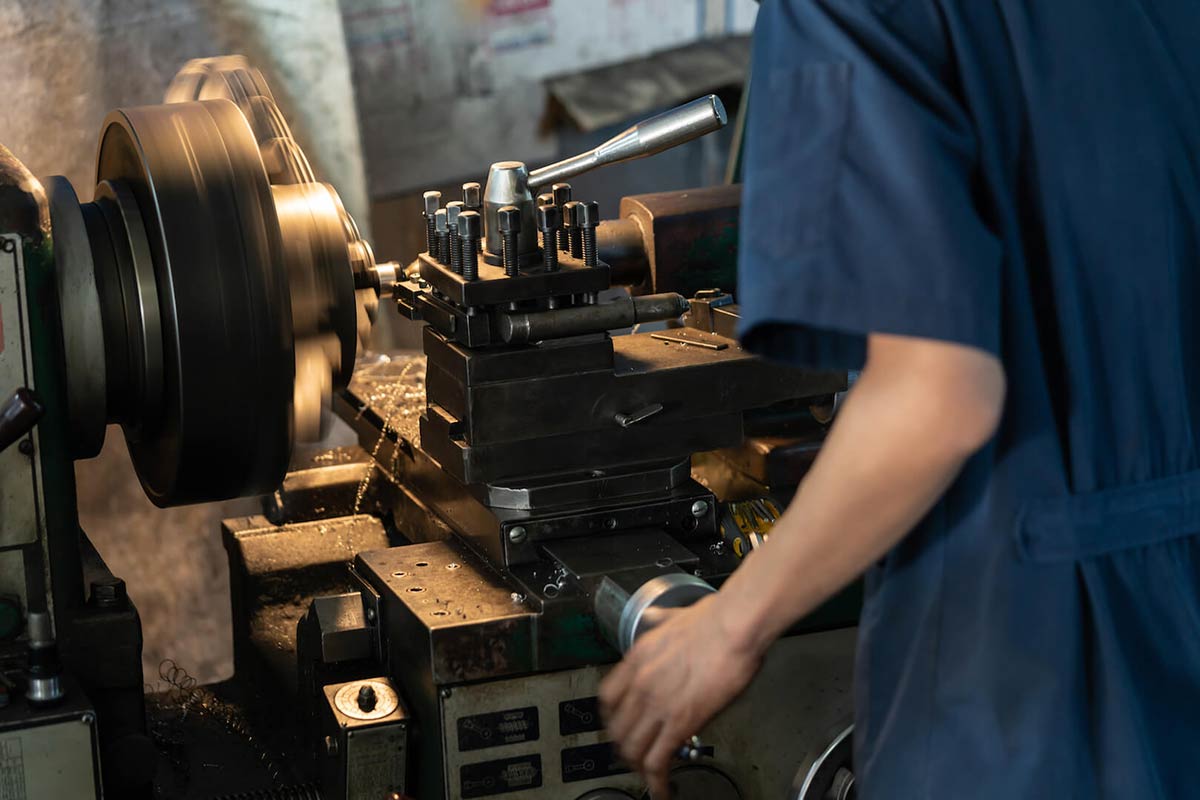

At Arabian Engineering (AET) we provide inspection services that involve assessment of components like the Rig Structures, Valves and Well and flow control systems to detect any defects, corrosion or damage that could compromise their integrity.

By utilizing our services industries can detect the flaws present in the components and prevent it which in turn reduce downtime, improve efficiency, and ensure safe operations, ultimately leading to higher profits and better performance.

Our Solutions & Benefits

Among various Inspection services, We at AET, provide NDT (Non-Destructive Testing) inspection services. Widely used in the oil & gas industries to ensure the integrity and safety of critical components, structures, and equipment. Our service helps the manufactures.

- To Prevent product failures.

- To Increase profitability.

- To achieve greater Reliability & Efficiency.

- To Improve Quality Control.

- To Compliance with Regulations.

This technique uses high-frequency sound waves to detect internal defects and measure the thickness of materials. UT is commonly used for inspecting pipelines, storage tanks, and pressure vessels.

MPT is used to detect surface and subsurface cracks and defects in ferromagnetic materials. It is commonly used for inspecting pipelines, offshore structures, and drilling equipment.

LPT is used to detect surface defects and cracks in non-porous materials. It is commonly used for inspecting welds, castings, and forgings.

FAQ - Inspection Services

The service that involves a third-party inspection or assessment of a product, service, process, or facility to ensure compliance with industry standards, regulations, and customer specifications.

visual inspections, dimensional inspections, non-destructive testing, pressure testing, material testing, and quality control inspections.

They help to ensure the safety, quality, and reliability of products, services, processes, and facilities. They also help to identify and mitigate risks and ensure compliance with regulations and customer requirements.

It is determined based on factors such as the scope and complexity of the inspection, the type of inspection method used, the number of inspectors required, and the location and accessibility of the site being inspected.

When choosing an inspection service provider, consider factors such as the provider's experience and expertise, reputation and references, accreditation and certifications, responsiveness and communication, and pricing and terms.