Maintenance

Brochure

Download our document to see specific data of the service and how we work.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

Our Services

How can we help?

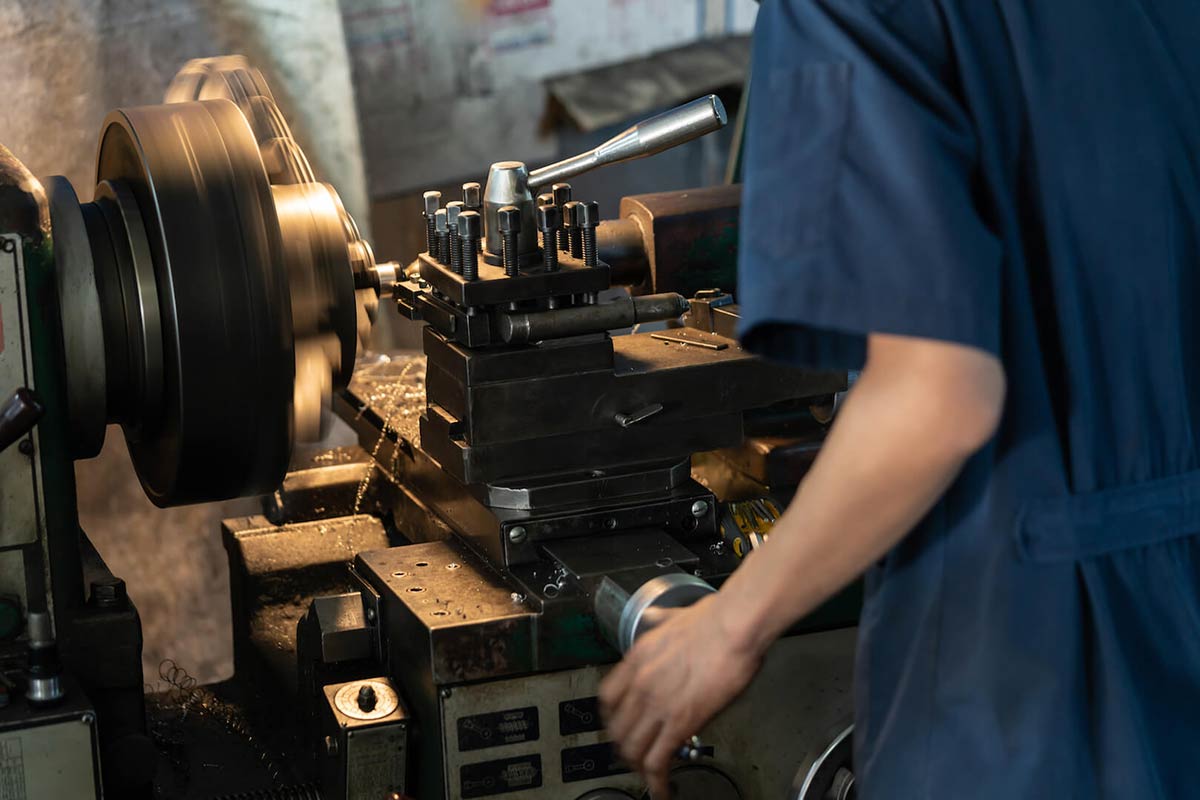

At Arabian Engineering (AET) we provide maintenance services that involve regular inspection of service-related products to ensure equipment reliability, safety, and longevity.

By utilizing our services industries can detect the flaws present in the components and prevent it which in turn reduce downtime, improve efficiency, and ensure safe operations, ultimately leading to higher profits and better performance.

Our Solutions & Benefits

We provide skilled professional team to maintain routine inspections to fix the flaws if any, to prevent equipment failures, prolong their lifespan, and ensure components or systems operate safely.

Our inspection/ maintenance services certify the product in accordance to the original design requirements, certification of the product against

- Certification of compliance

- Certificate of conformance

- Certificate of service

We at Arab Engineering our team of experts schedules the maintenance activities, such as cleaning, lubrication, and parts replacement, to prevent equipment breakdowns and extend the lifespan of the equipment. It includes tasks such as changing filters, inspecting valves and pumps, and performing regular oil analysis.

Our professional team uses data and analytics to predict when equipment failures are likely to occur and schedules the maintenance activity before the equipment fails, reducing the likelihood of unscheduled downtime and repair costs.

FAQ - Maintenance Services

The activity includes the process of ensuring that the equipment, machinery, and facilities used in oil and gas exploration, production, refining, and transportation are operating safely, efficiently, and reliably.

Common maintenance activities includes preventive maintenance, corrective maintenance, predictive maintenance, and reliability-centred maintenance. These activities can involve inspections, testing, lubrication, cleaning, repair, and replacement of equipment components.

Based on the manufacturer's recommendations, industry standards, and regulatory requirements. Maintenance can be performed on a fixed schedule (such as daily, weekly, or monthly), or it can be based on equipment condition monitoring and analysis.

Because equipment downtime can result in significant financial losses and safety risks. By ensuring that equipment is properly maintained, companies can reduce the risk of accidents, prevent equipment failures, and extend the lifespan of their assets.

High cost of equipment, the remote and harsh operating environments, the need for specialized skills and knowledge, and the regulatory compliance requirements. Additionally, the aging infrastructure in the industry can pose challenges for maintenance and repair.