Manufacturing

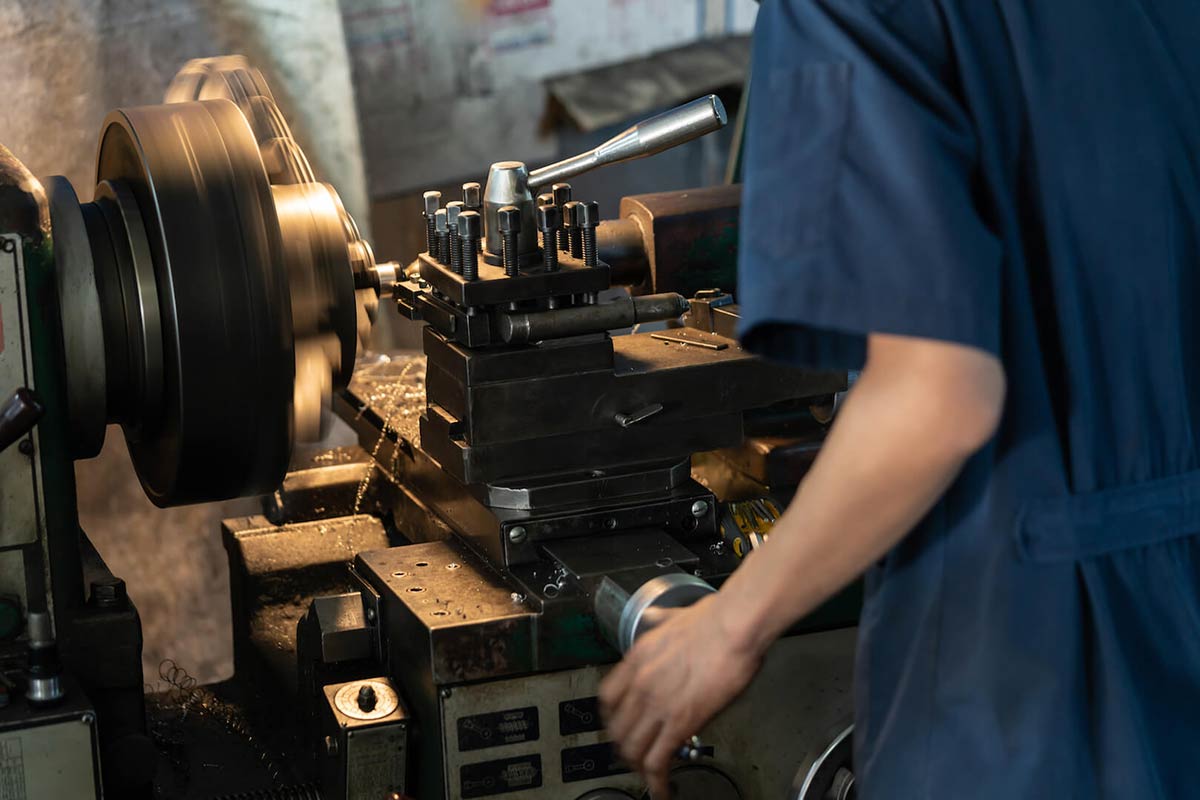

Manufacturing components in the oil and gas industry is a critical process that involves designing, creating, and assembling a variety of equipment and systems. These components are used in various stages of oil and gas exploration, production, processing, and transportation.

Manufacturing

Brochure

Download our document to see specific data of the service and how we work.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

Our Services

How can we help?

At Arabian Engineering (AET) we provide manufacturing services that involve designing, creating and assembling equipment’s that required by the clients. We work on designing components like drilling equipment’s, separation equipment’s, pumps and compressors, storage tanks and vessels, pipeline components, wellhead and Christmas tree equipment’s.

Our professional team follows different stages until final production that includes designing, prototyping and testing. Manufacturing process will be carried out by considering quality control and safety ensuring the component meets industry standard and regulations.

Stats & Charts

Modern industrial engineers typically use predetermined motion time system, computer simulation, along with extensive mathematical tools for modeling, such as mathematical optimization and queueing theory, and computational methods for system analysis, evaluation, and optimization.

Our Solutions & Benefits

At Arabian Engineering we perform manufacturing process as a part of inspection and maintenance services. When clients undergo flaws in their components, we help them fix their issues by taking necessary actions whether the component must be worked on to fix issues or to be replaced.

We provide services that includes fabrication, coating and welding to fix the issues that were met during inspection or maintenance activity. Our manufacturing services certify the product in accordance with the original design requirements, certification of the product against

- Certification of compliance

- Certificate of conformance

- Certificate of service

Our professional team provides fabrication service that involves cutting, bending, welding, and assembling metal components to create custom solutions for specific applications in the industry. Quality control and safety are critical considerations throughout the fabrication process to ensure that the components meet industry standards and regulations.

Coating is one of the option essential for protecting equipment and infrastructure from corrosion, wear and tear, and other forms of damage caused by harsh environments and operating conditions. We provide the service during maintenance activity after visual inspection if the components require.

Welding service can be carried out if the client requires in case of flaws to fix during inspection and maintenance. Joining metal components and structures that are exposed to extreme temperatures, pressures, and harsh environments uses welding process. We have professional team certified and trained for the process.

FAQ - Manufacturing Services

Fabrication is the process of creating or building metal structures or components from raw materials. It is used to create structures such as pipelines, drilling rigs, and offshore platforms.

Fabrication techniques used in industry include cutting, drilling, bending, rolling, and welding. The raw materials include carbon steel, stainless steel, and various alloys.

To protect equipment and structures from corrosion, erosion, and other forms of degradation in the harsh operating environment. They also provide a barrier against the effects of weathering, UV radiation, and chemical exposure.

Variety of techniques, including visual inspection, adhesion testing, thickness testing, and porosity testing. These tests help ensure that the coating or paint is applied correctly and provides adequate protection against corrosion and other forms of damage.

Epoxy, polyurethane, fluoropolymer, and ceramic coatings. The choice of coating depends on the specific application, the operating environment, and the level of protection required.